Liquid Penetrant Training (PT)

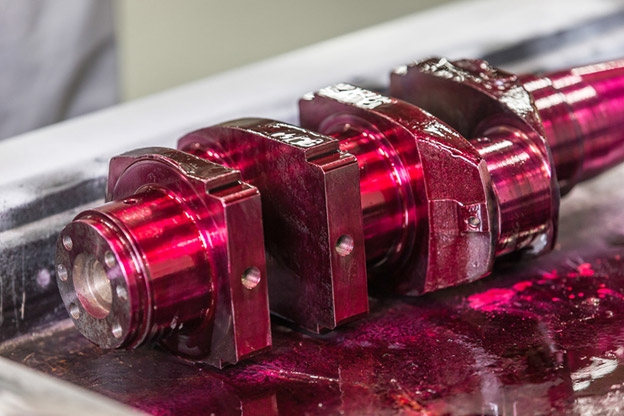

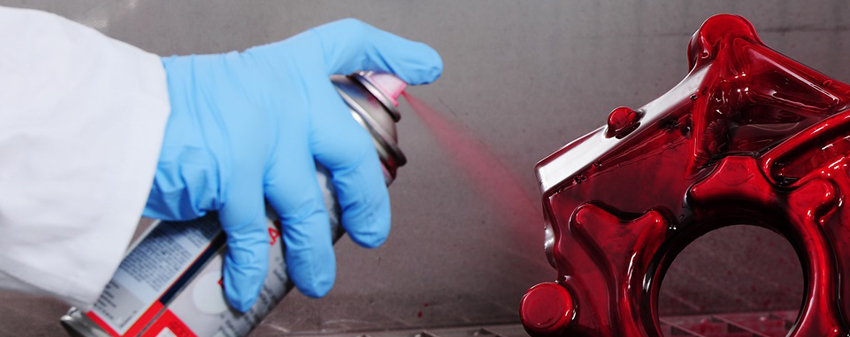

Liquid penetrant (careful examination of something) is a nondestructive testing method that shows/tells about surface breaking flaws by bleedout of a penetrating liquid colored with a visible or fluorescent dye from the flaw. The way of doing things is based on the ability of a liquid to be drawn into a "clean" (in other words, unobstructed) surface breaking flaw by (liquids moving up very thin tubes).

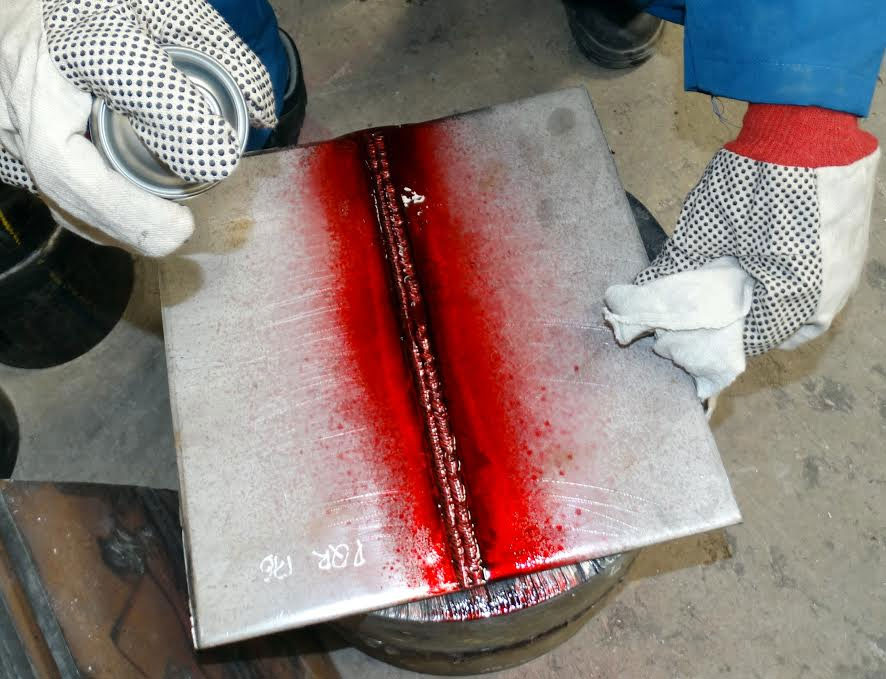

After the right/the proper period of time for penetration has papsed, called the "dwell time," excess penetrant on the surface is removed and a developer applied. The developer acts as a blotter and draws the penetrant from the flaw to show its presence. Penetrants with a visible dyed added (color contrast) require (good) enough white light to insure proper (careful examination of something), while penetrants with a fluorescent dye added need to be used in darkened conditions with an ultraviolet or "black light".

This method is used to inspect a variety of product forms including castings, forming/creatings, and weldments. The (related to what holds something together and makes it strong) steel, automotive, (related to oil from the ground), power generation, and outer space businesses are a few examples that use liquid penetrant (careful examination of something).

A Career in Liquid Penetrants

Careers can be in a variety of areas:

1.Service Inspection Companies

2.Smelters & Foundries

3.Rolling & Forging Mills

4.Petro Chemical & Refineries

5.Mining & Mineral Processing

6.Aircraft Maintenance & Manufacturing

7.Vehicle Maintenance & Manufacturing

8.Government Bodies

9.Engineering Firms

10.Research & Development Facilities

11.Education & Training

12.Equipment Manufacture & Sales

Course offered by UIC

1.PT LEVEL-I Training and certification as per SNT-TC-1A OR CP-189.

2.PT LEVEL-II Training and certification as per SNT-TC-1A OR CP-189..

3.Wide varity of flawed speicmen avaliable for practical training.

4.In house PCN and ASNT NDT L-III who will montor and look after for this program.